Always make those above you feel superior. If you make them feel insecure, you will spark resentment. Instead, allow them to take the credit for the work and stand by their accomplishments. The key is to make them feel good about themselves while you quietly advance behind the scenes. It’s about creating loyalty and avoiding any threats to their sense of power.

Document and Reinforce Standardized Work (Part 2 of 3)

Case Study: Boosting Productivity Through Standardized Work at PrecisionTek Manufacturing

PrecisionTek Manufacturing, a producer of high-tolerance aerospace components, was grappling with inconsistent product quality and rising rework costs. Operators followed different methods for completing the same tasks, leading to variation in cycle times and output. While best practices existed informally, they were not clearly documented or consistently reinforced across shifts and departments. This lack of standardization made it difficult for supervisors to identify process gaps, hindering both productivity and continuous improvement efforts.

To address these challenges, PrecisionTek launched a plant-wide initiative to document and reinforce standardized work as part of their Management Operating System (MOS). Cross-functional teams collaborated to map out key processes and create detailed work instructions for all critical production tasks, from machine setup to final inspection. These standards were posted at workstations and incorporated into training programs to ensure that all operators understood and followed the defined processes. Supervisors also began using checklists during shift reviews to reinforce adherence and gather feedback for improvement.

The results were compelling. Within 90 days, PrecisionTek experienced a 14% improvement in first-pass yield and reduced rework hours by 18%. Standardizing work processes also contributed to a 10% decrease in production cycle times, as operators were now performing tasks with greater consistency and fewer interruptions. The documented standards provided a clear baseline for identifying bottlenecks and implementing targeted process improvements, accelerating the company’s continuous improvement initiatives.

Beyond productivity gains, the cultural impact was equally positive. Employees reported increased confidence in their roles, knowing that they were following best practices that had been validated and supported by leadership. Supervisors found it easier to coach team members and measure performance objectively, while cross-training efforts improved as operators could now transfer skills across workstations with minimal disruption. By documenting and reinforcing standardized work, PrecisionTek laid a solid foundation for operational excellence and sustained productivity growth.

Never Outshine the Master (Part 1 of 3)

Always make those above you feel superior. If you make them feel insecure, you will spark resentment. Instead, allow them to take the credit for the work and stand by their accomplishments. The key is to make them feel good about themselves while you quietly advance behind the scenes. It’s about creating loyalty and avoiding any threats to their sense of power.

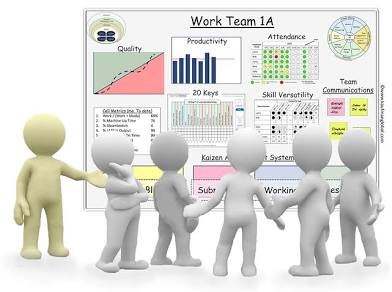

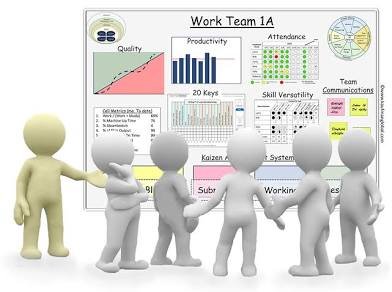

Document and Reinforce Standardized Work (Part 1 of 3)

One of the cornerstones of MOS is consistent execution. Define and document standard work processes clearly. Train teams on them and use them as a baseline for continuous improvement. Without standards, you can’t measure or manage effectively.

Establish a Cadence That Sticks (Part 3 of 3)

Industry Trends: Driving Productivity through a Consistent Cadence

In industries like manufacturing, engineering, supply chain, and services, leaders are increasingly recognizing that operational cadence is critical for driving consistency and productivity. According to a study by PwC, companies that implement structured rhythms, such as daily huddles and weekly planning cycles, are 24% more likely to achieve their operational targets. In manufacturing and warehousing, where variability can disrupt flow and efficiency, establishing a steady Management Operating System (MOS) cadence reduces firefighting and promotes proactive problem-solving. Organizations are moving away from ad-hoc meetings toward disciplined daily and weekly routines that ensure alignment and create predictability across teams.

Engineering and supply chain leaders are applying similar principles to improve project execution and process reliability. A report from Deloitte found that engineering teams using a formal cadence, including weekly design reviews and sprint retrospectives, shortened project lead times by an average of 15%. In the supply chain sector, consistent operational rhythms—such as daily logistics stand-ups and weekly inventory reviews—have helped reduce fulfillment errors and stockouts by as much as 18%. Leadership is realizing that when teams know when and how issues will be addressed, they are less likely to operate in crisis mode and more likely to make decisions based on data and trends.

Marketing and service industries are also embracing cadence-driven frameworks to improve execution and customer satisfaction. HubSpot reports that marketing teams with formalized weekly performance reviews and monthly campaign retrospectives experience a 19% higher success rate in achieving their KPIs compared to teams without a clear cadence. In services, companies that conduct regular client check-ins and internal team debriefs reduce customer churn by up to 10%. The key is consistency—when teams engage in regular performance conversations, they foster accountability, improve communication, and create space for continuous improvement.

Across sectors, the trend is clear: leaders are embedding cadence as a core element of their MOS to build operational resilience and drive performance. The rise of digital tools and collaborative platforms has made it easier to standardize and scale these rhythms across locations and departments. Whether it’s daily tiered huddles on a production floor or weekly planning sessions in a marketing agency, organizations with a cadence that sticks are better positioned to prevent surprises, respond quickly to challenges, and sustain high levels of productivity over time.

Establish a Cadence That Sticks (Part 2 of 3)

Case Study: Driving Productivity through a Consistent Cadence at Titan Components

Titan Components, a manufacturer of precision-machined parts, was facing inconsistent production performance marked by missed deadlines, reactive firefighting, and poor cross-functional communication. While the company had elements of a Management Operating System (MOS) in place—such as team meetings and performance reviews—these were irregular and varied widely between departments. Without a consistent cadence, production teams struggled to anticipate issues, and leadership found it difficult to align daily operations with strategic objectives.

To address these challenges, Titan Components launched an initiative to establish a structured and repeatable cadence across all levels of the organization. This included implementing daily shift huddles for frontline teams, weekly production planning meetings for supervisors, and monthly performance reviews with senior management. Each meeting followed a standardized agenda focused on KPIs, problem-solving, and forward-looking actions. Managers were trained to facilitate these sessions effectively, ensuring discussions stayed focused and outcomes were documented and tracked.

The impact was immediate and significant. Within two months, Titan saw a 20% improvement in schedule adherence and a 12% increase in overall equipment effectiveness (OEE). Issues that previously escalated unnoticed were now identified and addressed early through daily huddles, while weekly planning meetings helped teams proactively allocate resources and manage capacity. Monthly reviews enabled senior leadership to identify recurring patterns and systemic issues, leading to data-driven improvements in processes and resource planning.

More importantly, the company experienced a cultural transformation. Employees across all levels reported feeling more connected to company goals and more confident in their ability to manage daily challenges. The predictable cadence created operational discipline and reduced last-minute surprises, contributing to a more stable and productive environment. By embedding a consistent MOS rhythm, Titan Components not only enhanced its operational predictability but also laid the foundation for sustainable productivity gains and continuous improvement.

Establish a Cadence That Sticks (Part 1 of 3)

MOS is about rhythm. Whether it’s daily huddles, weekly planning, or monthly reviews, make sure every team level has a defined and repeatable cadence. A consistent MOS cycle prevents surprises and creates operational predictability.

Make Metrics Visible to Everyone (Part 3 of 3)

Industry Trends: Improving Productivity by Making Metrics Visible

In today’s competitive landscape, visibility of key performance indicators (KPIs) has become a critical driver of operational excellence across industries like manufacturing, engineering, marketing, services, warehousing, and supply chain. A recent study by Gartner found that organizations that integrate real-time performance data into frontline operations are 20% more likely to meet or exceed their productivity targets. In manufacturing and warehousing environments especially, visibility tools such as digital dashboards, performance boards, and Andon systems are being increasingly deployed to ensure employees can immediately identify variances and take corrective action. This transparency eliminates information silos and helps bridge the gap between management and frontline workers, fostering quicker decision-making and operational agility.

Engineering and supply chain leaders are also embracing the “metrics visible to everyone” philosophy to combat inefficiencies. According to a report by McKinsey, companies that provide engineers and supply chain teams with open access to project and operational KPIs improve cross-functional collaboration and reduce project cycle times by up to 12%. Visibility promotes alignment across complex workflows, as engineers can now track critical metrics such as design iteration rates, procurement lead times, and defect rates in real time. This level of openness drives team engagement and reinforces continuous improvement mindsets throughout the product lifecycle.

In marketing and service-based industries, performance transparency has proven to be equally valuable. Research by HubSpot shows that marketing teams who regularly review and display performance metrics, such as conversion rates and campaign ROI, experience a 17% improvement in campaign effectiveness. Similarly, service teams that track and share KPIs like customer satisfaction scores and resolution times improve customer retention by as much as 10%. Making metrics accessible to all levels of the organization fosters data ownership and encourages teams to collectively focus on meeting customer expectations and business objectives.

Overall, industry leaders recognize that real-time visibility is no longer just a “nice to have,” but a competitive necessity. With Industry 4.0 technologies and cloud-based analytics platforms, organizations can now automate the capture and sharing of operational data across departments and facilities. Leaders who champion metric transparency are not only driving measurable improvements in productivity and efficiency but are also cultivating cultures rooted in accountability, empowerment, and data-driven decision-making — traits that are essential for long-term success in today’s volatile and fast-paced market environments.